Our Laboratory Services

The Biospherical Instruments (BSI) Calibration Facility is well-equipped with dedicated optical benches and customized test and calibration equipment. We offer the following services for optical calibration and characterization, in addition to services for the calibration of ancillary sensors such as water temperature, depth (pressure), and instrument tilt.

It is also possible for our customers to bring your instruments and standards to us for comparison with our in-house units. The measurements from your instruments can also be compared with the solar measurements of our SUV-100 spectroradiometer (permanently installed on BSI's rooftop facility), as well as comparing your profiling instruments with our own in-house sensors.

Our Calibration & Characterization Laboratory

The calibration laboratories at Biospherical Instruments are designed to calibrate systems before shipping to customers, recalibrate returned instruments, and to validate the performance and measurements new instrumentation and technologies.

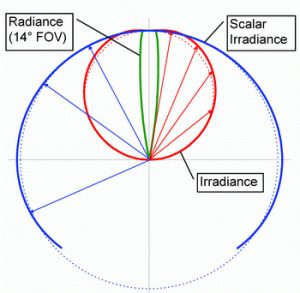

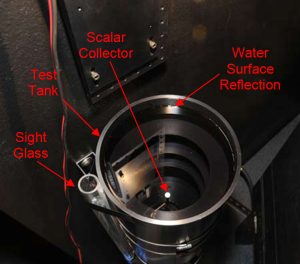

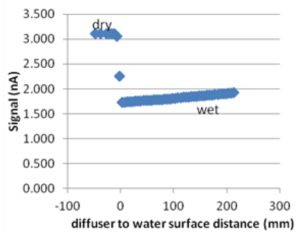

The calibration laboratory has several optical benches: two are used for irradiance calibrations (with one set aside for lamp transfers), one for radiance calibrations, one for in-air directional testing of irradiance and radiance collection optics, one for directional testing of radiometers fully immersed in filtered water, and one for the spectral characterization of radiometers. There is also a vertical irradiance bench used to determine immersion coefficients (the change in optical collection efficiency when a radiometer is used immersed in water).

The primary standards used are FEL Standards of Spectral Irradiance issued by the U.S. National Institute for Standards and Technology (NIST). BSI maintains a library of these standards and draws on that library to generate working standards. Finally, reference radiometers with hybrid optics composed of arrays of microradiometers at different wavelengths plus a spectrograph are maintained and used for frequent checks of the standard lamps.

The calibration laboratory also maintains calibrated voltmeters, shunts, temperature, and pressure reference devices.

Calibration facilities are available to third parties on a contract basis.